Everything You Need to Know About Liquid Control Valves

597

0

·

2021/06/12

·

3 mins read

☕

WriterShelf™ is a unique multiple pen name blogging and forum platform. Protect relationships and your privacy. Take your writing in new directions. ** Join WriterShelf**

WriterShelf™ is an open writing platform. The views, information and opinions in this article are those of the author.

Article info

Tags:

Date:

Published: 2021/06/12 - Updated: 2021/06/12

Total: 556 words

Like

or Dislike

More from this author

More to explore

/cdn.vox-cdn.com/uploads/chorus_image/image/57545427/DH7civuV0AEq1qN.0.jpg)

Water, oil, gas, and more drive production. Without a network of pipes to flow by, everything would be at a halt. For example, Los Angeles alone produces some 167 billion gallons of clean water a year to customers.

What do industry titans Kraft Velveeta, Coca-Cola, or Pacific Oil and Gas have in primary with the city of Los Angeles?

They all use flow control valves to control the movement of fluids or gases by their systems. Although fluid cheese, sugar syrup, and natural gas are very diverse, the devices that own their flow are alike.

Read on to learn about various kinds of valves and how they run.

What is Your Method Loop?

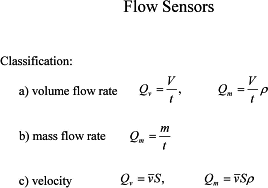

If you are moving a product, there may be several points where some important variable requires control. For instance, pressure, flow, temperature, level, etc., all influence your outcome.

One little change in a number can replace other points, which in turn influences the next loop. Valve controls form liquid flows to limit variations. The limit means variability and boost energy.

Rotating Kinds of Control Valves

Valves can be automated or performed manually. There are various kinds, each proper for explicit uses—control valve body types. We can split them into two groups: long and twisting.

Turning flow control valves have an element that rotates within the flow to change it.

Full or Segmented Ball Valves

A rotating control valve fit for on or off service, deep pressure, and flow variability. Segmented ball valves are suitable for slurry.

Ball valves can be used to change the flow of liquids. The ball acts as a fitting, which prevents or enables complete or incomplete flow by the valve.

The cost is within globe valves and butterfly valves.

Butterfly Valves

A lower cost and less accurate option to other kinds of rotating valves. They use less area and are available in large widths. It is a ring-shaped, inline device with a disc in the center that works as a plug.

Plug Valves

Another lower-cost option to ball valves. Used at low-pressure falls under high flow velocities.

Linear Control Valves

Linear control valves use the natural line movement of a sliding stem to regulate flow.

Globe Valves

Globe valves are linear flow control valves. They come in three primary types: single-seat, double-seat, or three-way.

Fit for a type of flow features and give direct control of flows. Best for clear fluids. It serves to be the most valuable option.

Gate Valves

A kind of linear control valve is also recognized as a knife or guillotine valve and is used for separation or cutoff. Not fit to change or restrict flow. Usually, they obstruct low-pressure gas and airflow. They come in single and dual seat variants.

Conclusion

The choice of the correct flow control valves for your project circuit is critical. Cost-effectiveness, property, and security are on the line. Keep the flow of fluids and gases flowing easily. Mechanical transport of liquids and gases is part of many commodities, from strength to foodstuffs.

Relying on the quality of the items moved, you might require rotary or linear valves. As essential as the choice of flow valves is the selection of actuators. Actuators give the quick response and automation needed for precise method control. Let our specialists help you pick the proper control valve from our wide range. Contact us today.